Key Features:

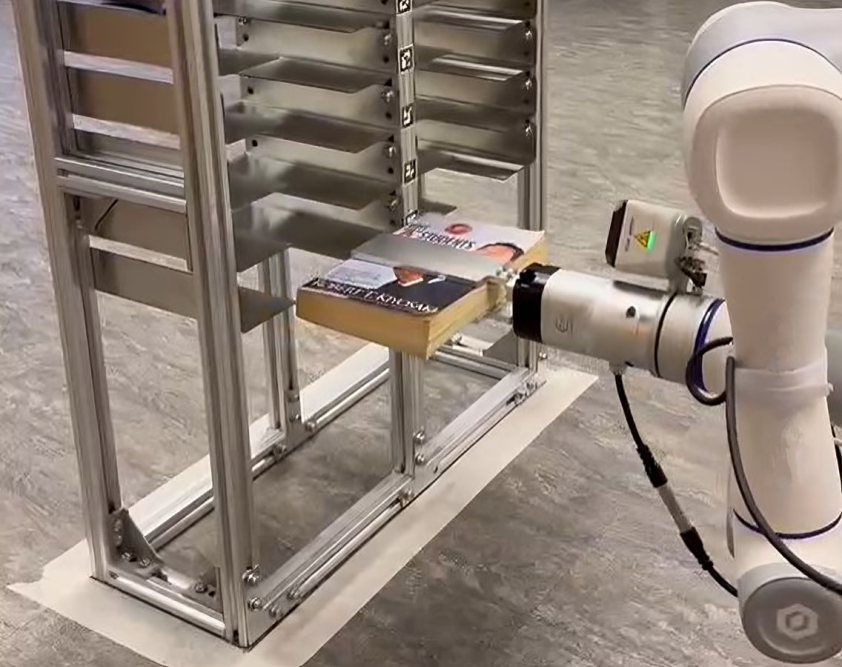

6-Axis Design: The robotic arm features a 6-axis design that provides a wide range of motion and flexibility, allowing it to tackle intricate tasks and adapt to diverse environments.

Rapid Retrieval and Storage: With lightning-fast movements and advanced motion control, the ASRS Robotic Arm can quickly and accurately retrieve and store items from high-density storage racks, maximizing throughput.

Exceptional Precision: Boasting an accuracy of ±0.05 mm and repeatability of ±0.03 mm, the ASRS Robotic Arm ensures consistent and reliable placement of items, minimizing errors and damage.

Modular and Scalable Design: The ASRS Robotic Arm’s modular construction allows for easy integration into existing warehouse layouts and seamless expansion as your storage and retrieval needs grow.

Intelligent Inventory Management: Seamlessly integrate the ASRS Robotic Arm with your warehouse management software to optimize inventory tracking, order fulfillment, and supply chain visibility.

Enhanced Safety Features: Equipped with advanced safety sensors, collision detection, and collaborative operation modes, the ASRS Robotic Arm prioritizes the safety of your workforce while operating efficiently.

Reduced Operating Costs: Automate your storage and retrieval processes to lower labor costs, increase operational efficiency, and improve overall productivity.

Applications

The ASRS Robotic Arm Solution is designed to revolutionize a wide range of warehouse and logistics applications, including:

Warehousing and Distribution: Streamline your storage, order picking, and material handling processes to improve throughput and accuracy.

E-commerce Fulfillment: Rapidly retrieve and package items to meet the demands of high-volume, fast-paced e-commerce operations.

Manufacturing Logistics: Integrate the ASRS Robotic Arm into your production line to seamlessly manage raw materials, work-in-progress, and finished goods.

Cold Storage and Pharmaceuticals: Leverage the ASRS Robotic Arm’s precision and safety features to handle temperature-sensitive and delicate products.

Fleet Management System:

Asset tracking: This feature allows administrators to track the location and status of individual robots in real-time, providing visibility into the operational status of the entire fleet.

Maintenance scheduling: The system can automate the scheduling of maintenance and repairs for individual robots, ensuring that they are kept in good working order and minimizing downtime.

Route optimization: For fleets of mobile robots, the system can help to optimize the routes taken by the robots to minimize travel time and reduce congestion.

Remote control: Provide remote control capabilities, allowing administrators to monitor and control individual robots from a central location.